Quartz glass - everything you need to know about it!

Technical glass is a broad group of materials that play a huge role in everyday life, but also in industry and science. One of the most valued types is the quartz variety, which is increasingly used in modern technologies, medicine and consumer electronics.

We explain what quartz glass is, what properties it has, where it is used and how much it costs. This will make it easier for you to understand why and in what cases it is worth investing in it.

What is quartz glass?

It is a type of technical glass made from almost pure silica ( SiO ₂), i.e. natural quartz. It does not contain any sodium, calcium or boron admixtures, which translates into extraordinary chemical purity and unique physical properties of this product.

It is produced in two main ways: by melting natural quartz (fused glass) or synthetically – from purified silicon dioxide . The latter process allows to obtain a material of even higher purity, which is important in photonics or the semiconductor industry.

Silica glass is not transparent to all wavelengths of light—it can transmit ultraviolet (UV), visible, and infrared (IR) radiation. It is this wide transmittance and high-temperature resistance that makes it a versatile material.

What is quartz?

Quartz is one of the most common minerals on Earth. Chemically, it is silicon dioxide , a compound made of one silicon atom and two oxygen atoms. It can be found in nature in many different forms - both as transparent, colorless crystals (e.g. rock crystal), and in the form of colored varieties, such as amethyst, citrine, pink quartz or smoky quartz. Natural quartz is exceptionally hard (7 on the Mohs scale), chemically resistant and transparent to many wavelengths of light. After cleaning and melting, it becomes an excellent material for the production of, among others, technical glass with the highest parameters.

It has a very wide range of applications, for example in industry as a raw material for the production of glass, ceramics, and electronics (e.g. quartz resonators in watches and computers), in jewelry, it is valued as decorative precious and semi-precious stones. It is also used by companies operating in the modern technology sector, where its purity and temperature resistance are important.

Quartz glass - properties

Compared to other materials, this one stands out with an interesting set of properties. First of all, it is a material of very high chemical purity, which means it does not react with most substances. This is important, for example, in analytical laboratories and precision industries.

Thermal resistance

It can operate at temperatures reaching up to 1100°C continuously, and in some cases for short periods up to 1300°C.

Low thermal expansion

Does not crack under sudden temperature changes (high resistance to thermal shock).

High optical transparency

Transmits light across a wide range of wavelengths, including UV, visible light and IR, depending on the glass type.

Chemical resistance

It is unaffected by most acids and bases, with the exception of hydrofluoric acid.

High mechanical strength and hardness

It is more resistant to scratches and abrasion than ordinary glass.

Excellent dielectric properties

That is why it is used in electronics and photonics.

These features make SiO ₂ glass one of the most versatile and reliable materials used in many demanding fields.

How is quartz glass different from regular glass?

Quartz glass differs from ordinary glass primarily in its chemical composition and physical properties. While ordinary glass, such as the popular soda-lime glass, contains, in addition to silica, also admixtures of sodium oxides, calcium and other additives that improve plasticity and lower the melting point, quartz consists almost exclusively of pure silica ( SiO ₂), often in over 99.9%. This difference in composition translates into the unique properties of the material - the quartz variety is much more resistant to high temperatures and thermal shock. It can operate at temperatures reaching 1100 - 1300 ° C, and the melting point is as much as around 1713 ° C, while ordinary glass softens at 500-600 ° C. It also transmits ultraviolet radiation better and is much more chemically neutral, which is why it is used for special tasks and is used in laboratories, industry and modern technologies.

Quartz glass - application

The actual beginning of quartz glass production is considered to be the 1930s, when the technology of melting pure quartz ( SiO₂ ) using an electric arc was developed. The first products, which were created in Germany and the United States, were used in laboratories and the optical industry. However, the development of silica melting and purification technology allowed the production of synthetic quartz glass of even higher purity in subsequent decades. This paved the way for its use in, among others, the semiconductor and laser industry.

Below are some of the most important areas where it is used on a significant scale:

Chemical and pharmaceutical industry

SiO ₂ glass is used to produce laboratory equipment, chemical reactors, pipes, flasks and vessels resistant to strong chemical reagents and high temperatures.

Lighting technology

Due to its excellent UV transmittance and resistance to high temperatures, quartz material is used as a cover for UV-C lamps (bactericidal), halogen lamps, incandescent lamps and reflectors.

Electronics and photonics industry

In the electronics industry, they are used in the production of semiconductor wafers, optical fibers, precision lenses and in laser devices.

Medicine and laboratories

It is used for the production of laboratory vessels, spectrophotometric cuvettes, thermometers, test tubes and specialized components for biological and chemical research.

Space and aviation industry

Due to its extreme resistance to temperature and radiation, silica glass is used in components of devices used in space conditions.

Home and utility technology

Although less common, quartz material is also used in household appliances – e.g. in oven windows, coffee machine heaters, and UV lamp housings for disinfection.

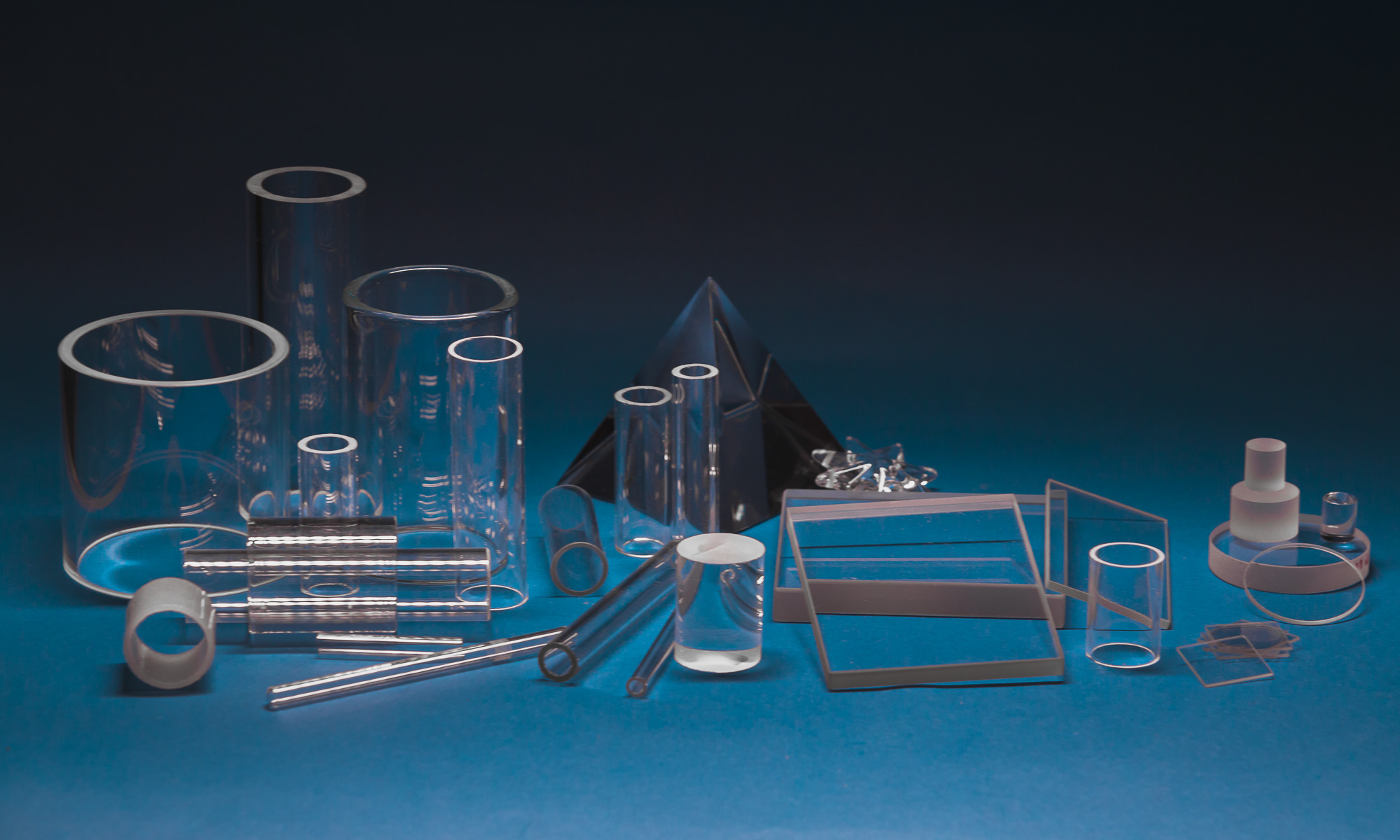

From laboratories to industry – the use of pipes, rods and plates

Pipes, plates, rods and custom products made of pure silica material are components for industries requiring the highest precision and resistance to extreme conditions. These products are used in research laboratories, chemical, pharmaceutical, semiconductor and optoelectronics industries.

Pipes and rods with high optical transparency and temperature resistance are essential, among others, in installations for the transmission of aggressive substances or in heating devices.

Plates and blocks made of this type of material are used to build thermal shields, measuring windows and components of devices operating in difficult environments.

It is also possible to make custom-made details in accordance with the customer's technical documentation, so the product can be adapted to a specific need.

Quartz glass and melting point

One of the most convincing features of this material is its high melting point. 1713°C is a value far above the melting points of most other types of glass, so this type can be used in extremely hot environments without the risk of deformation or disintegration of its structure.

This feature is particularly important in the steel and metallurgical industry, as well as wherever contact with liquid metal or intense thermal radiation occurs.

UV quartz glass - transparency and radiation blocking

Depending on the type, silica glass can be transparent to UV radiation (UV-transmissive glass) and is then used in disinfection lamps, analyzers, spectrometers or UV-blocking. UV-blocking glass is used where it is necessary to protect, e.g. food or museum exhibits from harmful radiation.

Therefore, when choosing this material, it is worth knowing what range of light spectrum it should be adapted to. In the medical and laboratory industry, quartz glass that transmits UV-C is most often used, because it allows the operation of germicidal lamps.

Quartz glass - price

SiO ₂ glass costs is not clear – it all depends on the type of product, its processing, dimensions and purpose.

The price can range from a dozen or so zlotys for small elements (e.g. tubes or rods), through several hundred zlotys for precise optical glass, to thousands of zlotys in the case of specialist laboratory equipment or industrial components. However, the price of this material goes hand in hand with its unique properties and reliability. Check out our offer of quartz glass .

Is it worth choosing quartz glass?

Definitely yes, if you want a material with the highest technical parameters. This is a solution that works wherever other types of glass fail. Resistance to high temperature, chemicals, radiation and mechanical damage means that it has not only many applications, but also a real impact on the quality, safety and efficiency of processes.