Our offer

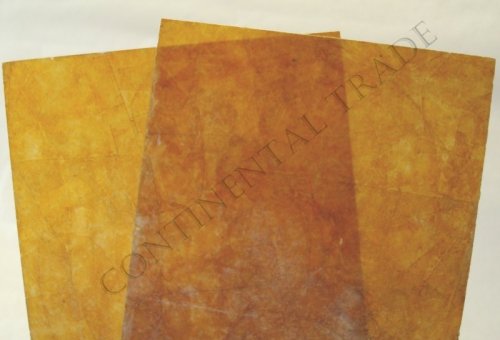

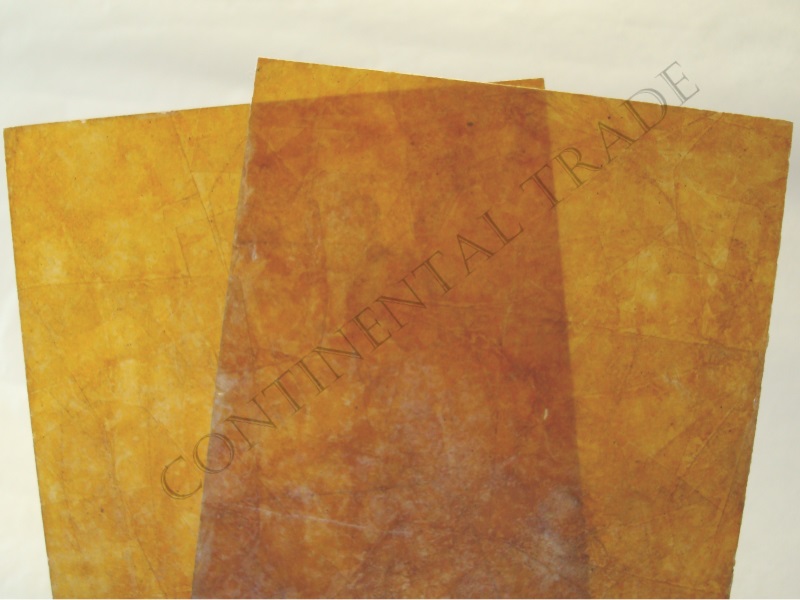

Hot molding mica plates

Hot molding mica sheets are produced from natural muscovite mica splittings bonded with a thermoplastic resins either shellac, epoxy or alkyd-vinyl by applying adequate heat and pressure. The amount of bond content range from 18% to 22% depending on type of product demanded. The relatively high amount of bond facilitate the mica to slip relative to each other during the molding process as necessary in assuming the desired contour.

Hot molding mica sheets are produced from natural muscovite mica splittings bonded with a thermoplastic resins either shellac, epoxy or alkyd-vinyl by applying adequate heat and pressure. The amount of bond content range from 18% to 22% depending on type of product demanded. The relatively high amount of bond facilitate the mica to slip relative to each other during the molding process as necessary in assuming the desired contour.

These sheets are rigid at room temperature but soften when heated at temperature between 100 °C to 140 °C and could easily be molded into practically any shape upon the application of either hot or cold process. With further cure, the sheets form into rigid well bonded structure retaining the shape of their molded forms.

Molding sheets bonded with shellac provides optimum moldability having an excellent overall properties and have been traditionally most popular, while epoxy or alkyd-vinyl bonded sheets offer toughness and durability under severe mechanical stress applications.

Alkyd resin-bound sheets stay flexible at room-temperature and is cured completely at 180 °C. Whereas, shellac resin-bonded sheets stay rigid at room-temperature and have to be preheated to gain flexibility before curing it completely at 150 -160 °C to form a rigid and robust insulation.

Application

Armature coil ground-insulation, armature slots, windings and coil insulation, end-winding turn insulation, bracing rings and V-Ring manufacturing.

Beautiful amber color, light permeability, interesting texture and the ability to create almost any shape, make plates bonded with shellac are also used in non-standard applications, e.g. in the manufacture of chandeliers, lampshades and furniture elements.

Offer

We offer hot molding micanite sheets made by depositing highly-flexible, thin films of high-quality muscovite mica splittings on top of each other till the required thickness is attained. As resin shellac is used. Shellac resin-bonded sheets stay rigid at room-temperature and have to be preheated to gain flexibility before curing it completely at 150°C to form a rigid and robust insulation.

Availability

Standard sheet sizes are:

- Size (Standard):

1000 x 1000 mm

500 x 1000 mm - Thickness :

0.20 – 2.0 mm

(Sheets can be shared to custom sizes)

Packing

Sheets are packed in airtight robust wooden boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

10 months at ≤ 20°C in dry condition

While every attempt has been made to verify the source of the information, no responsibility is accepted for accuracy of data.

Product Data Sheet

| Properties | Test Method | Value |

|---|---|---|

| Thickness tolerance | IEC 60371-2 | ± 0.1 mm |

| Mica content | IEC 60371-2 | 84 ±2 % |

| Resin content | IEC 60371-2 | 16 ±2 % |

| Breakdown voltage | IEC 60243-1 | ≥ 25 kV/mm |

| Winding property | - | good |