Glass ring tubular sight glass type 640 PN 16

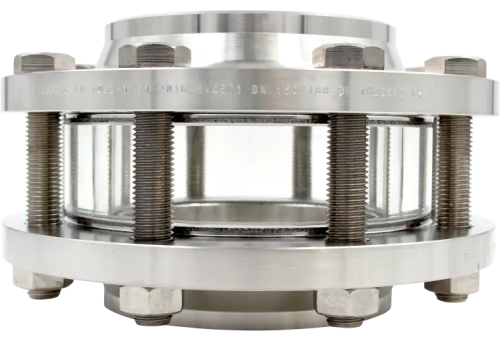

The intermediate flange tubular sight glass type 640 is a compact solution for visual process monitoring of media in pipelines. The design as an intermediate flange model allows for space-saving installation between flanges in accordance with DIN EN 1092-1.

With a working pressure of up to 16 barg, the type 640 is suitable for a variety of industrial applications. The compact design allows for subsequent integration into existing systems – even with limited space availability.

Even with larger nominal sizes, operating pressures over 16 barg can be realized, offering additional flexibility.

The standard version made of thermally hardened borosilicate glass is designed for operating temperatures up to 280 °C and offers high resistance to thermal and chemical stress.

- V-flange type 11 according to DIN EN 1092-1

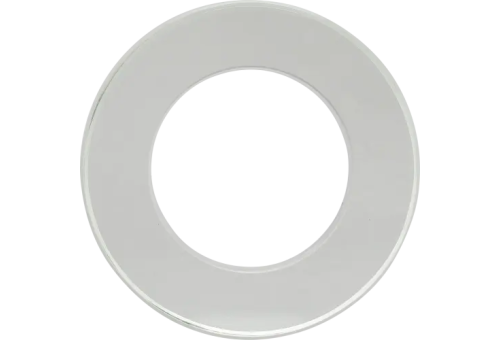

- Gasket

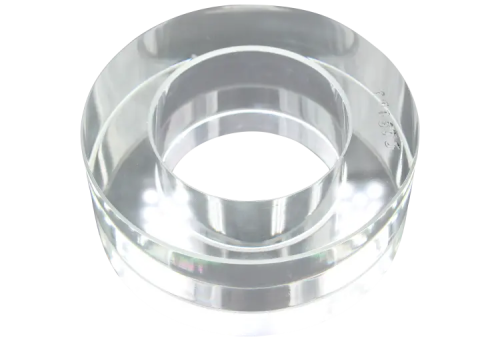

- Glass ring tubular sight glass type 640

- Gasket

- V-flange type 11 according to DIN EN 1092-1

Cross-section

drawing

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Di [mm] | 14 | 18 | 22 | 29 | 38 | 44 | 55 | 71 | 83 | 108 | 132 | 160 | 208 | 260 | 310 | 341 | 392 | 443 | 494 |

| Da [mm] | 40 | 45 | 58 | 68 | 79 | 88 | 102 | 122 | 138 | 158 | 188 | 212 | 268 | 320 | 378 | 430 | 482 | 532 | 585 |

| Weight² ⁴ | 0,13 | 0,16 | 0,27 | 0,36 | 0,46 | 0,56 | 0,71 | 0,94 | 1,16 | 1,27 | 1,71 | 1,85 | 2,73 | 3,28 | 4,41 | 6,2 | 7,1 | 7,8 | 8,9 |

| Weight³ ⁴ | 0,07 | 0,08 | 0,13 | 0,18 | 0,22 | 0,27 | 0,34 | 0,46 | 0,58 | 0,62 | 0,83 | 0,9 | 1,32 | 1,61 | 2,17 | 3,18 | 3,64 | 4,02 | 4,55 |

| PS ² ⁵ | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 10 | 10 | 10 | 10 | 10 | 10 |

| PS ³ ⁵ | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 10 | 10 | 10 | 8 | 8 | 8 | 6 | 6 | 6 | 6 | 6 |

| ² Borosilicate glass ³Acrylic glass ⁴Weight in [kg] for L = 50 mm ⁵max. operating pressure in [barg] Other materials, sizes, lengths and flange standards on request |

|||||||||||||||||||