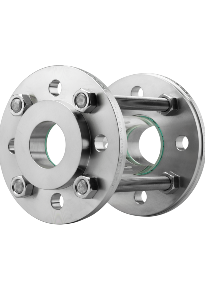

Tubular sight glass type 620 PN10/16

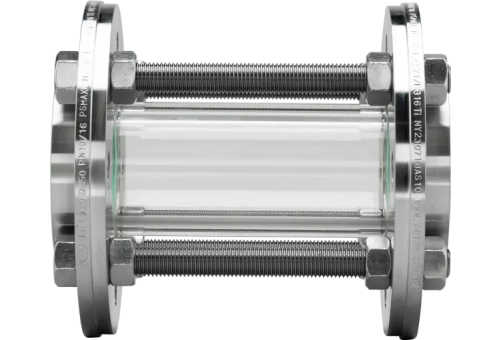

The ACI tubular sight glass type 620 offers a complete 360° view of the process medium through a borosilicate glass cylinder. Encased between two high-quality flanges made of stainless steel or carbon steel, it enables comprehensive visual control of your system.

The standard version is equipped with flanges made of stainless steel 1.4571 (316Ti) – a material known for its excellent corrosion resistance and durability in industrial applications. For less demanding applications, a variant with flanges made of P265GH is also available. In addition, special materials such as Hastelloy®, duplex steels, or other high-performance alloys can be realized upon request.

The glass tube is made of industrially tested borosilicate glass 3.3 according to DIN ISO 3585. It impresses with high temperature and chemical resistance as well as very good optical properties.

The sealing is done with individually selectable flat seals from a wide range of materials – from classic fiber material seals to high-quality special materials like PTFE (Teflon®), NBR, novaphit® MST-XP, or KlingerSil® C4400. This allows the gasket to be optimally adapted to the medium, temperature, and pressure.

In nominal sizes up to DN 50, the tubular sight glass type 620 is designed for operating pressures of up to 16 barg.

Thanks to the precise coordination of flange, gasket, and glass, the fitting is almost dead space-free, making it suitable for hygienically demanding processes.

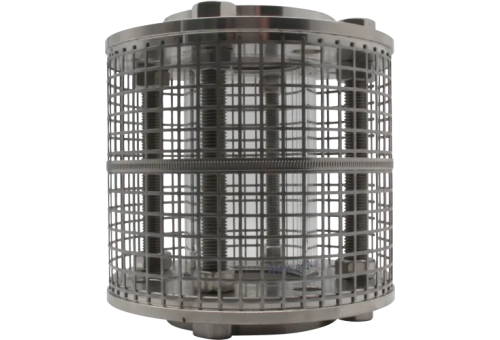

For areas with increased mechanical hazards – e.g., when installed under walkways – we recommend optional impact protection covers. These reliably protect the glass tube from falling objects and minimize the risk of unplanned failures or damage.

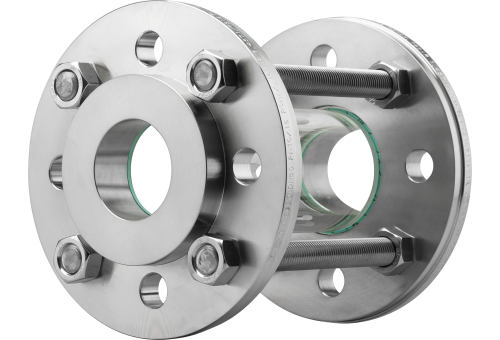

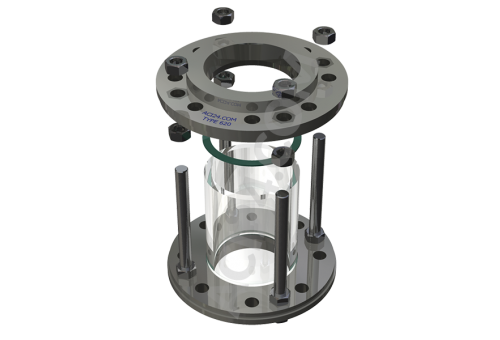

- Nuts

- Flange

- Threaded rod

- Borosilicate glass cylinder

- Gasket

Cross-section

drawing

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250⁴ | 300⁴ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| K [mm] | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 410 |

| DF [mm] | 41 | 54 | 64 | 74 | 84 | 98 | 118 | 134 | 154 | 184 | 208 | 264 | 320 | 370 |

| D [mm] | 95 | 105 | 115 | 145 | 150 | 175 | 195 | 200 | 225 | 250 | 295 | 345 | 400 | 460 |

| PS [barg] | 16 | 16 | 16 | 16 | 16 | 16 | 10 | 10 | 10 | 8 | 7 | 5 | 4 | 4 |

| Number of bores and diameter according to DIN EN 1092-1 - PN10/16 (from the nominal size DN 200 only PN 10) | ||||||||||||||

| 4) Special construction, only upon prior request. Other sizes, lengths, and flange standards available upon request | ||||||||||||||