Longitudinal sight glass fitting type 336 PN 6 for welding in or on

The ACI sight glass type 336 is a lightweight version that offers a significantly enlarged viewing opening compared to our type 330 at relatively low operating pressure up to max. 6 barg. This design combines the functions of our round sight glasses like type 318 and our level indicators for container wall mounting type 330.

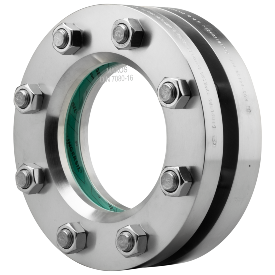

The fitting is equipped with a sight glass plate made of high-quality borosilicate glass similar to DIN 7081 (or according to customer specifications). This is securely framed between seals and tightly screwed to ensure permanent tightness and high pressure resistance.

Standardly, the sight glass type 336 is made of stainless steel 1.4571 (316Ti) - a material that is characterized by high corrosion resistance and durability. On request, the design is also available in many other materials, suitable for specific requirements and applications.

The sealing of the fitting is done with flat seals adapted to your needs from a wide range of materials. In addition to the common fiber material seals, it also offers more advanced materials, such as PTFE (Teflon®), NBR, novaphit® MST-XP, KlingerSil® C4400, and many other branded seals.

If the maximum application temperature of borosilicate glass DIN 7081 does not meet your requirements or if the process conditions pose a problem even for the highly resistant borosilicate glass, a mica protective disc specially adapted for the fitting provides additional protection against temperature and steam. FEP or Halar® coatings additionally protect the borosilicate glass against aggressive chemicals or caustics.

- Screws

- Cover frame

- Glass cushion

- Sight glass

- Gasket

- Base frame

Cross-section

drawing

| BL [mm] | 250 | 310 | 370 | 430 | 490 | 550 | 610 | 670 |

|---|---|---|---|---|---|---|---|---|

| SL [mm] | 180 | 240 | 300 | 360 | 420 | 480 | 540 | 600 |

| Weight [kg] | 5.6 | 6.9 | 8.2 | 9.6 | 10.9 | 12.2 | 13.6 | 14.9 |