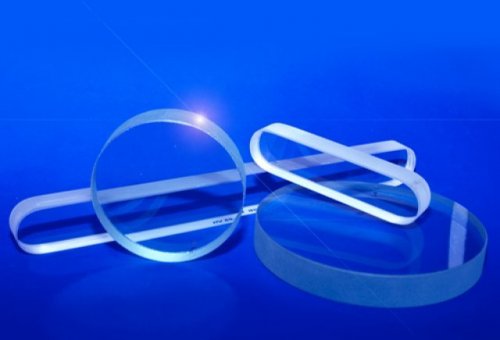

Transparent

Transparent level gauge glasses offered by us are made by a recognized, global companies like Klinger, Maxos, Spectraglass of high-quality borosilicate ("extra hard") or aluminosilicateglasses. Glass in the production process is subjected to a two-sided polishing and toughening. This results in products characterized by high mechanical strength and high resistance to alkalis, acids and condensates. In the production process is conducted constant and precise control of transparency and the dimensions of manufactured glass.

Transparent (smooth) level gauge glasses are used to read the liquid level directly or with the use of CCTV (industrial television). They can be (type TA 28) used up to 180 bar / 356°C for aggressive environments affecting (interacting) the glass (eg. saturated steam, hot water, alkalis) and up to 300 bar / 400°C for soft environments. Glass must be protected from the medium side through the mica shields. They are especially recommended for environments contaminated, viscous and highly corrosive.

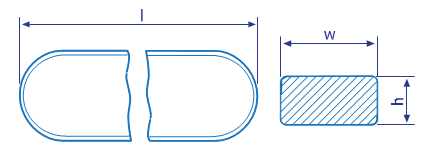

Depending on the width and thickness there are four basic types of transparent level gauge glasses:

- type A - width 30 mm, thickness 17 mm

- type B - width 34 mm, thickness 17 mm

- type H - width 34 mm, thickness 22 mm

- type TA 28 - width of 27.6 mm, 16.8 mm

In addition, the occasionally encountered also:

- Type C - width of 20 mm, thickness 12 mm

- Type D - width 25 mm, thickness 15 mm

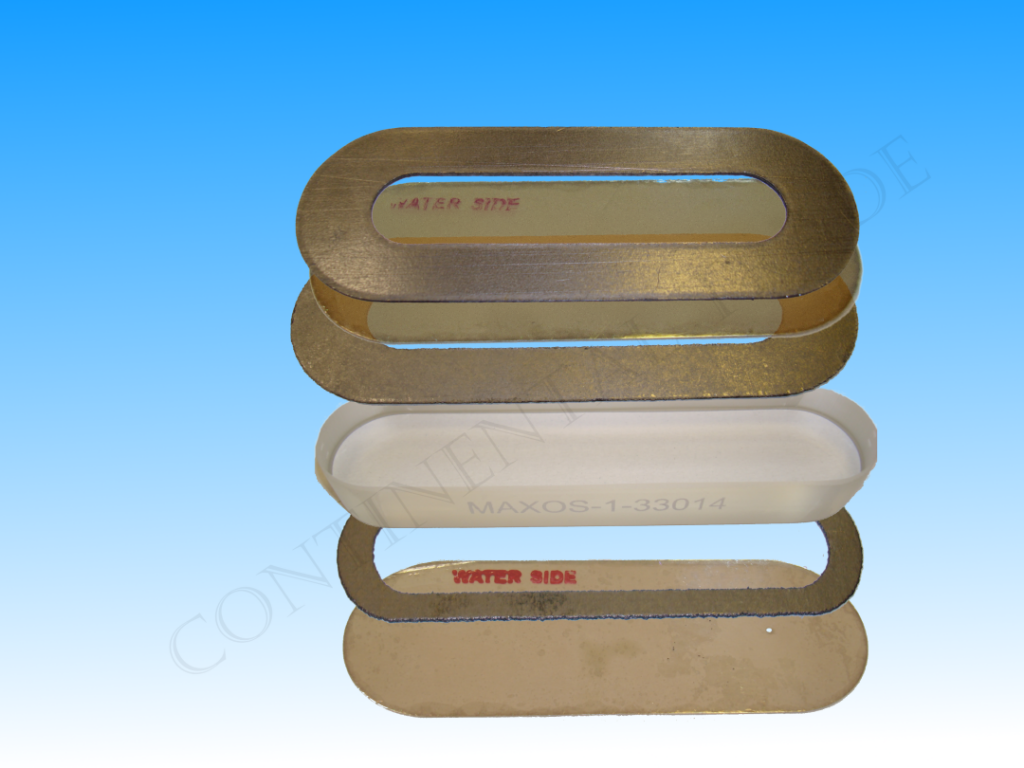

Transparent level gauge glasses are supplied in sets with gaskets and mica shields or separately.

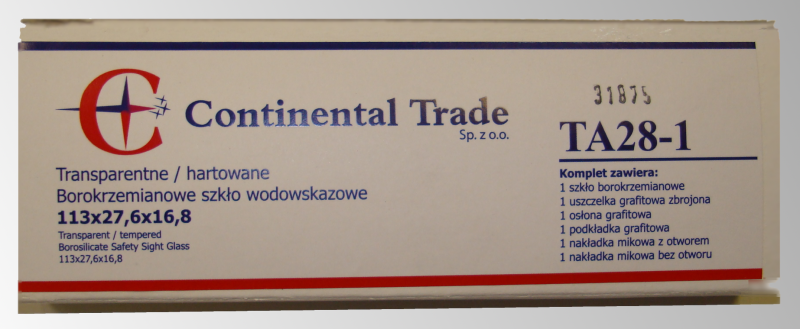

Sample contents of the set.

|

The set, packaged in a common box, consists of:

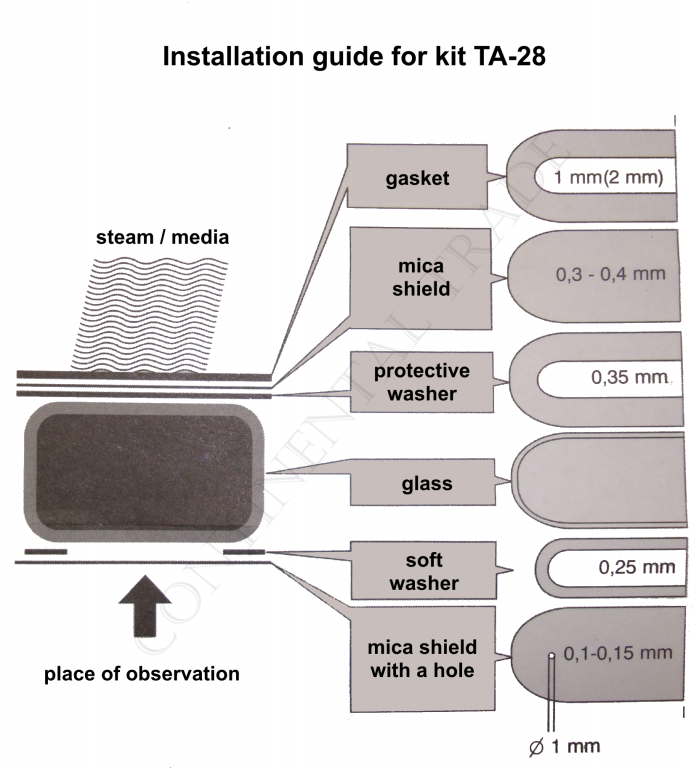

In all TA-28 sets, soft washers and protective washers are made from graphite foil. In set TA-28-I gasket is made from graphite laminate KlingerGraphite type SLS (see desc. here), but for sets TA-28-III .. TA-28-IX KlingerGraphite type PSM is used (see desc. here). In sets type A, B, H all washers are made from KlingerSil plate type C-4430 (see desc. here), but gaskets are made from graphite laminate KlingerGraphite type SLS (see desc. here).

It is good to know, that the role of the mica shield installed on the outside (ie, on the side of the viewer) is to reduce the thermal shock to which gauge glass is exposed, working on the one hand, in an environment of high temperature (steam, hot water), and on the other, with a low (room) temperature environment. Outer mica shield helps to a longer faultless operation of the set. The hole made in the shield, protects against moisture staying between the glass and mica while mounting assembly and relieves pressure above and below the shield during normal operation. |

box: |  |

| set of elements: |  |

|

| installation guide: |  |

We offer transparent glass meet the following standards:

- ÖNORM M 7354 (Austrian standard)

- DIN 7081 (German standard)

- JIS B 8211 (Japanese standard)

- ÖMV-Spez. H 2009 (Austrian factory standard of the petrochemical concern ÖMV-AG, Vienna)

- MIL-G-16356 D (regulations the US Navy)

- Esso Eng. Spec. 123 (Esso Research and Engineering Co. - New Jersey)

- S.O.D. Spec. 123 (Standard Oil Development Company - New Jersey)

- BS 3463 (British Standard)

We also provide glass unusual: manufactured according to individual customer technical requirements, custom sizes and custom shapes.

Scope of application:

| Type A | Type B | Type H | Type TA 28 3) | |||||

|---|---|---|---|---|---|---|---|---|

| [bar] | [°C] | [bar] | [°C] | [bar] | [°C] | [bar] | [°C] | |

| For soft environment, not affecting aggressive on the glass ie. oils, hydrocarbons, etc. | 240 | 120 | 290 | 120 | 340 | 120 | - | - |

| 160 | 400 | 800 | 400 | 230 | 400 | - | - | |

| 0 - 10 | 430 | 0 - 10 | 430 | 0 - 10 | 430 | - | - | |

| For aggressive environment acting on the glass, eg. saturated steam, hot water, alkalis | 35 1) | 243 | 35 1) | 243 | 42 1) | 253 | 120 2) | 324 |

| 70 | 300 | 85 | 300 | 85 | 300 | 180 | 356 | |

1) For steam pressures above 35 bar is recommended to use mica shields.

2) For steam pressures above 120 bar can be used only glasses TA-28-I.

3) Glass type TA 28 can be used only with mica shields.

Dimensions:

| Size | TYPE A | TYPE B | TYPE H | TYPE TA 28 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | L | W | H | L | W | H | L | W | H | |

| I | 115 | 30 | 17 | 115 | 34 | 17 | - | - | - | 113 | 27,6 | 16,8 |

| II | 140 | 30 | 17 | 140 | 34 | 17 | 140 | 34 | 22 | - | - | - |

| III | 165 | 30 | 17 | 165 | 34 | 17 | 165 | 34 | 22 | 163 | 27,6 | 16,8 |

| IV | 190 | 30 | 17 | 190 | 34 | 17 | 190 | 34 | 22 | 188 | 27,6 | 16,8 |

| V | 220 | 30 | 17 | 220 | 34 | 17 | 220 | 34 | 22 | 218 | 27,6 | 16,8 |

| VI | 250 | 30 | 17 | 250 | 34 | 17 | 250 | 34 | 22 | 248 | 27,6 | 16,8 |

| VII | 280 | 30 | 17 | 280 | 34 | 17 | 280 | 34 | 22 | 278 | 27,6 | 16,8 |

| VIII | 320 | 30 | 17 | 320 | 34 | 17 | 320 | 34 | 22 | 318 | 27,6 | 16,8 |

| IX | 340 | 30 | 17 | 340 | 34 | 17 | 340 | 34 | 22 | 338 | 27,6 | 16,8 |

| X | - | - | - | 370 | 34 | 17 | - | - | - | - | - | - |

Note: transparent level gauge glasses are supplied in sets with gaskets and mica shields or separately.

If you can not find the size - please contact us.

While every attempt has been made to verify the source of the information, no responsibility is accepted for accuracy of data.