Soda lime glass

Soda lime glass—also referred to as soda glass or soda lime silica glass—is the most widely used type of glass in the world. Known for its excellent formability, durability, and cost-efficiency, soda lime glass is used in countless everyday applications, from window glass to bottles, jars, and products made of glass. This type of glass is made primarily from glass raw materials such as silica (sand), sodium carbonate, and calcium oxide, all of which influence the chemical composition of glass and its physical properties.

What is soda lime glass made of?

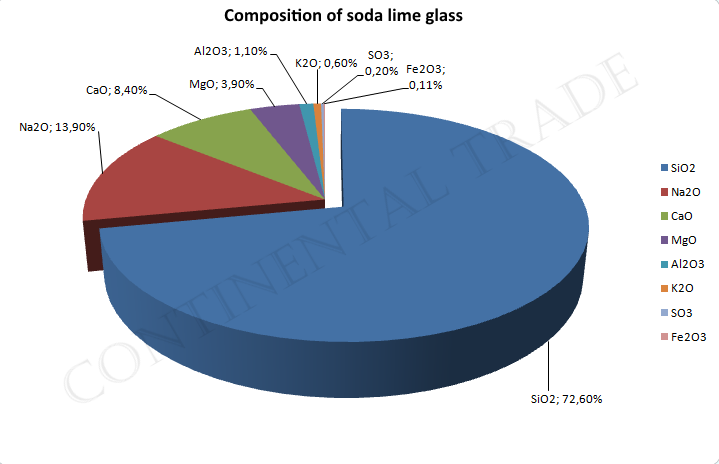

The typical composition of soda lime glass includes:

- ~70–75% silica (SiO₂)

- ~12–15% soda (Na₂O)

- ~10% lime (CaO)

These components of glass are fused at high temperatures during the formation of glass. The chemical formula of glass may vary slightly depending on the specific application, but soda and lime remain the defining constituents. The chemical formula of limestone, primarily CaCO₃, plays a role as a lime source. When heated, it decomposes to provide calcium oxide.

This glass composition gives soda lime its distinctive properties: moderate chemical resistance, ease of melting, and high optical clarity. The addition of other materials such as alumina, magnesia, or potassium glass can enhance certain mechanical properties of glass like hardness and thermal stability.

Characteristics and properties of soda lime glass

Understanding the characteristics of glass is essential for industries relying on performance and safety. Some core soda lime glass properties include:

- Density of glass: approximately 2.5 g/cm³

- Glass density and mass of glass affect how it behaves under stress and its suitability for various structures.

- Hardness of glass: ranges from 5 to 6 on the Mohs scale

- Moderate bending strength of glass

- Thermal conductivity: ~1.0 W/m·K

- Thermal expansion coefficient: ~9 × 10⁻⁶ /K

- Softening point: ~720°C

- Its glass chemical composition provides transparency, resistance to mild acids, and excellent shaping capabilities. However, the strength of glass varies with treatment; for example, chemically toughened glass or tempered glass shows dramatically improved performance under load.

Thermal properties: at what temperature does glass break?

The thermal resistance of soda lime glass is lower than that of borosilicate or quartz glass. It can typically withstand temperatures up to 150°C–200°C. But at what temperature does glass break? Sudden changes above 60–70°C can cause fracture due to thermal shock. This makes it unsuitable for high-heat applications unless modified through chemical toughening of glass or used as tempered glass.

Despite these limits, soda lime remains dominant due to its ideal balance between performance and cost. It meets standard needs for safety glass composition and strength in most architectural and packaging contexts.

Glass manufacturing and production technology

The manufacture of glass—particularly soda lime glass production—is a highly refined industrial process. It begins with the blending of glass raw materials: silica sand, soda ash (Na₂CO₃), and limestone (CaCO₃). These ingredients define both the glass chemical formula and the quality of the final product.

Steps in glass production technology

- Batch mixing of raw materials.

- Melting in a furnace (~1500°C).

- Forming into sheets, containers, or fibers.

- Controlled cooling (annealing) to relieve internal stress.

Float glass production—the method used for most window panes—involves floating molten glass on a bed of molten tin, creating flat, uniform sheets. This process revolutionized the manufacturing process of glass by improving quality and reducing costs.

Soda lime glass vs. other types of glass

Soda lime is just one variety in the spectrum of glass and its types. Here’s how it compares:

- Silicate glass: General term for glass with a silica base, including soda lime and borosilicate.

- Lead free glass: Safer and more environmentally friendly than traditional crystal glass.

- Lead glass properties: Offers high refractive index for decorative items but less commonly used today due to toxicity concerns.

- Potassium glass: Provides increased scratch resistance; often used in display screens.

- Tempered glass properties: Enhanced safety and strength through thermal treatment.

Types of silicate glass vary by the additives used, influencing traits like glass chemical composition, melting point, and toughness. Window glass composition, for example, favors clarity and workability, aligning with soda lime’s strengths.

Chemically etched and tempered glass

For specialized uses, soda lime glass may undergo post-processing such as:

- Chemically etched glass: Used for decorative effects and privacy without compromising translucency.

- Tempered glass: Achieved through rapid cooling; it’s four to five times stronger than standard glass.

- Density of tempered glass remains close to that of standard soda lime, but its improved mechanical properties of lass make it ideal for high-impact environments.

These enhancements expand the soda lime glass applications to include automotive, architectural, and even electronic fields.

Applications and end uses

Thanks to its versatility, soda lime is used in a broad range of products made of glass, including:

- Sand glass containers: bottles, jars, and drinking glasses

- Glassware for home and commercial use

- Window panes and mirrors

- Float glass sheets for building façades

- Chemically etched glass panels for interior design

- Lead free glass and safety glass options for consumer electronics

Soda glass properties such as transparency, processability, and cost-efficiency drive its global demand. The ability to adjust the glass composition makes it adaptable across industries—from construction and packaging to electronics and automotive design.

Why soda lime glass?

In summary, soda lime glass is a cornerstone of modern glassmaking. Its favorable chemical composition of glass, relatively low glass density, ease of glass manufacturing technology, and suitable soda lime glass properties make it the default choice for countless applications. When clients ask, “What is glass made of?” or “Glass—what is it?”, soda lime glass is often the answer. It strikes the perfect balance between cost, performance, and sustainability.

Whether you're sourcing window glass composition, designing safety glass, or considering the formation of glass for new innovations, soda lime remains a reliable, proven solution. We offer custom solutions in soda glass, soda lime glass production, and a variety of glass products tailored to your technical and design requirements.

The characteristics of soda lime glass

Characteristics:

- can be chemically strengthened to increase the mechanical strength *

- can be thermally enhanced (tempered) to increase the thermal shock resistance and mechanical strength

- can be machined, coated optically, chemically etched, sandblasted, colored or laminated

- has a good flatness and surface quality

- the lowest cost of manufacture of the glass in sheet form

* Mechanical strength is defined as the overall material's ability to withstand stress and strain. The mechanical strength of tempered glass or chemically reinforced maybe 4 times greater than normal glass.

| SiO2 | 72,60% |

| Na2O | 13,90% |

| CaO | 8,40% |

| MgO | 3,90% |

| Al2O3 | 1,10% |

| K2O | 0,60% |

| SO3 | 0,20% |

| Fe2O3 | 0,11% |

|

Typical Modulus of Rupture for 50% Probability of breakage

|

Typical Design Stress for 0.8% Probability of breakage

|

Spectral Transmission

Properties:

| Density ( @ 18 °C) | 2 500 kg/m3 |

| Mohs hardness | 5 - 6 |

| Modulus of elasticity (Young’s) | 72 GPa |

| Shear modulus | 30 GPa |

| Poisson’s ratio | 0,23 |

| Coefficient of thermal stress | 0,62 MPa/°C |

| Thermal conductivity | 0,937 W/(m K) |

| Specific heat | 0,88 kJ/(kg K) |

| Coefficient of linear expansion | 8,3 * 10 -6 °C |

| Index of refraction (@ 380 - 780 nm) | 1.5 |

| Softening point | 715 °C |

| Annealing point | 548 °C |

| Max. working temperature: | |

| - not toughened | 110 °C |

| - toughened | 150 °C |

| Thermal shock Δ : | |

| - not toughened | 50 °C |

| - toughened | 118 °C |

| Dielectric Constant (@ 20°C) | 7.75 |

| Specific Resistivity: | |

| 1000 Hz | @25°C: 9.7 log R ohm/cm @100°C: 9.1 log R ohm/cm @250°C: 6.5 log R ohm/cm |

| 60Hz | @25°C: 11 log R ohm/cm |

FLOAT glass

Name of glass - float - is, in fact, the name of a technological process in which the liquid glass mass solidifies on the surface of the molten tin. Description of the process is available eg. on page https://en.wikipedia.org/wiki/Float_glass. The name float is typically used for flat soda-lime glass.

Float glass is a product base, which is used to produce other types of specialized glass having improved properties. The way to the final product goes mostly through additional treatment: toughening, annealing, heat strengthening, laminating, and more.

Soda-lime float glass used in technical applications is usually subjected to a toughening process. During toughening, the glass sheet is heated to a temperature of about 700 °C and then quickly cooled with cold air. This changes the microstructure of the glass. An additional effect of toughening is to give a glass the safety features. Toughened glass is very hard on the outside and soft inside, whereby the stresses in the glass structure at the time of breakage cause the disintegration of the glass sheet into small pieces with blunt edges. During the hardening process is to be expected possibility of glass deformation, but no greater than specified in the table below.

Limits for the distortion of glass in the toughening process, measured on the edge of the glass.

| Glass thickness | Max deformation for 1m 1) |

|---|---|

| 3 mm | 3 mm |

| 4 mm - 5 mm | 2 mm |

| 6 mm - 10 mm | 1,5 mm |

1) in proportion to the dimensions. For example, a sheet of glass having a thickness of 8 mm and dimensions 600 x 600 mm due to toughening process has right to deform: 0.6 m × 1.5 mm = 0.9 mm. This fact should be considered at the design stage.

Toughened glass has an increased mechanical and thermal strength in comparison with a "normal" glass (see. tables below).