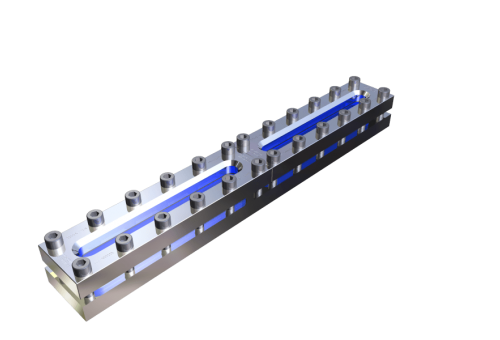

RECTANGULAR LEVEL INDICATOR SIGHT GLASS

SHORT DESCRIPTION - SIGHT GLASS LEVEL INDICATOR

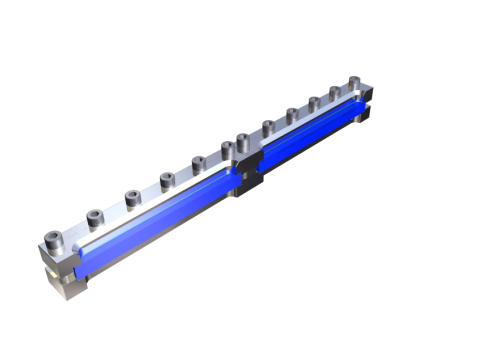

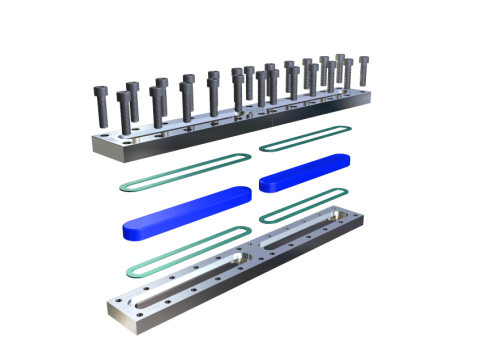

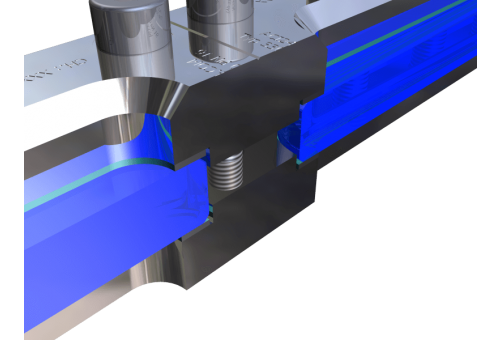

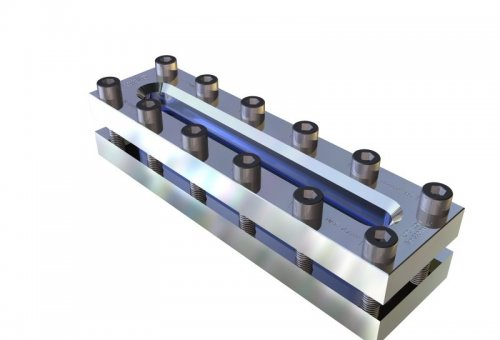

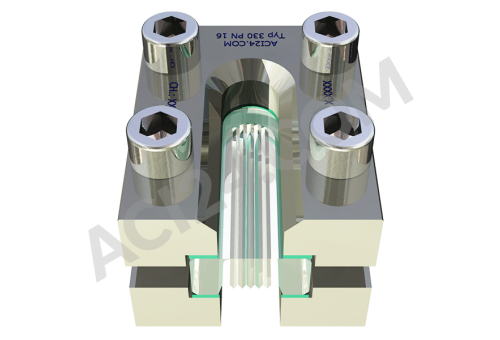

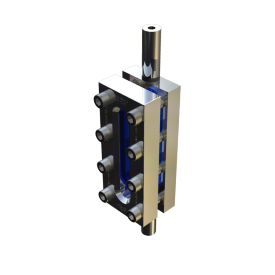

The ACI level indicator Type 330 is an easy to mount fitting for the industrially proven borosilicate sight glass plates according to DIN 7081. The base flange of Type 330 is set into the wall of a container or pipe and is fixed all-round with a welding seam. The base flange has an indentation for glass and seals, which are held by a cover flange. Type 330 only needs a very low torque for the fixing screws, whilst still achieving very reliable sealing.

Type 330, like most of our fittings, is available in a range of materials, including standard types of container steel such as S235, or standard stainless-steel alloys such as 1.4571 or 1.4404, but high-performance materials such as Hastelloy or duplex alloys are available on request.

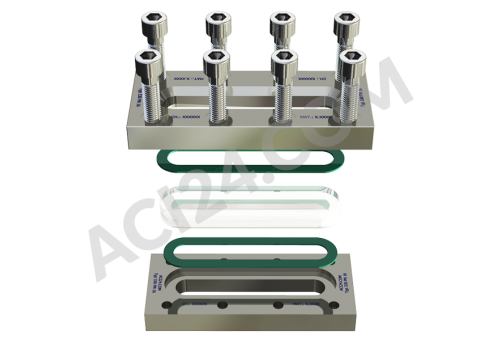

For the sealing, we use tried and tested high-quality flat seals from well-known manufacturers such as KlingerSIL C4400 or novaphit MST. It is also possible to supply pure PTFE seal plates and soft seals such as NBR or EPDM directly.

The industry norm DIN 7081 includes the use of sight glasses of different lengths in the “Transparent” and “Reflex” versions. Transparent glass means simple, smooth glass plates. This type can, should the operating conditions require it, be fitted with protective layers made of mica or other materials such as KEL-F. We recommend the reflex type, if operating conditions allow it, for use with clear, colourless liquids. Due to the grooves contained in this type, the meniscus in the liquid phase can be seen clearer than with the transparent variety.

Read on for technical data and detailed views.

Material:

Base and top frame:

- 1.4571; 1.4404, 1.4462, RSt 37-2 / H II / Other materials on request

Screws:

- A4-70

Seals:

- depending on the application

Glass:

- Reflections -or- Transparent glass according to DIN 7081 or DIN 8903

Shape:

- Rectangular Sight Glass as level indicator for visual inspection of tanks, boilers and silos

Nominal size:

- size from 140 mm up to 1000 mm

- Other sizes on request

Nominal pressure:

- PN 16 or PN 40

- For operating pressures up to max. 35 bar depending on the model

Temperature:

- temperature: 100 ° C or 243 ° C

- depending on the glass and seal selection.

Special Feature:

- Lloyd’s Register Design Approval available

Options:

- Optional versions are possible.

Gasket selection:

- PTFE (200°C)

- FKM (200°C)

- NBR (100°C)

- C4400 (150°C)

- Silicone (200°C)

- EPDM (140°C)

- Graphite (320°C)

Installation instructions:

After welding in the base flange, check whether the sealing surfaces have warped! If necessary, rework must be carried out. The operating pressure does not apply to the base frame, which must be checked together with the pressure device according to AD data sheet B9!

BL = overall length / SL = visible length

| BL | SL | Concealed view | Kg(16 bar) | Kg(35 bar) |

|---|---|---|---|---|

| 140 | 79 | 0 | 2,8 | 3,4 |

| 170 | 124 | 0 | 3,2 | 4,0 |

| 220 | 174 | 0 | 4,0 | 5,0 |

| 250 | 204 | 0 | 4,6 | 5,7 |

| 300 | 264 | 0 | 5,3 | 6,7 |

| 310 | 264 | 0 | 5,6 | 7,0 |

| 350 | 304 | 0 | 6,3 | 7,8 |

| 370 | 324 | 0 | 6,6 | 8,2 |

| 400 | 354 | 0 | 7, | 8,9 |

| 500 | 454 | 1x46 | 9,1 | 11,4 |

| 600 | 574 | 1x46 | 10,7 | 13,4 |

| 620 | 574 | 1x46 | 11,1 | 13,9 |

| 700 | 654 | 1x46 | 12,5 | 15,7 |

| 740 | 694 | 1x46 | 13,2 | 16,5 |

| 800 | 74 | 1x46 | 14,2 | 17,8 |

| 930 | 884 | 2x46 | 16,7 | 20,9 |

| 1000 | 954 | 3x46 | 18,2 | 22,8 |