Our offer includes sight glasses made of various materials, depending on environmental conditions (temperature, pressure, aggressive media). The properties of various glass materials are described on page Types of materials in chapter Our offer/Technical glass. The basic types of materials used for the manufacture of sight glasses are:

- soda-lime glass - widely available, cheap, working temperature up to 280 °C,

- borosilicate glass - particularly suitable for use in aggressive environments (acids, alkalis, water vapor), working temperature up to 350 °C,

- aluminosilicate glass - working temperature up to 660 °C,

- glass-ceramics - thermal shock resistant, working temperature up to 750 °C,

- quartz glass - with a broad spectrum light transmittance (from ultraviolet to infrared), working temperature up to 1100 °C,

- sapphire products - working temperature up to 2000 °C.

To improve the strength, the machined glass is subjected to toughening and annealing. In order to increase the resistance of sight glasses on the aggressiveness of the working environment and in the use of high temperatures and pressures, additional use of mica shield is recommended. Mica disc working as shields are described here. If you need this solution - please contact us.

Round sight glasses are delivered separately or in a set with gaskets. Gaskets for sight glasses are described here.

We offer sight glasses manufactured by leading brands such as: Spectraglass, Klinger or Maxos, which guarantees high quality and stability of parameters.

Safety precautions when using sight glass discs:

- Whenever a sight glass assembly has been taken apart it is urgently recommended in accordance with DIN 7080/ DIN 8902 that the glass disc and gaskets are replaced by new ones. That is particularly important in the case of pressure vessels and/or aggressive media. The following extract from DIN 7080/DIN 8902 text is verbatim:

Sight glass discs may only be installed by personnel who have been informed fully about the following requirements:

- care in handling sight glass discs

- cleaning of recesses, sight glass discs, gaskets and other parts i. e. removal of foreign bodies (e. g. swarf), prior to installation/reassembly

- even tightening of retaining bolts

Sight glass discs that have been removed after operating use must not be re used.

- Planned maintenance:

Sight glass discs should be included in routine maintenance and periodically checked visually or using ultrasound wall thickness measuring means. In the event of damage, a glass disc must be promptly exchanged, with the plant first having been brought to a standstill. The service life of a sight glass, relative to the particular vessel in which it is mounted, should be established by regular and careful visual check of its condition.

Caution: Completely demineralised water may dissolve glass – especially intensive periodical inspection required! - Breakage of a sight glass:

In spite of careful installation and recommended use, sight glass discs can, on rare occasions, suffer breakage through external influences. In order to prevent the entry of glass particles into products of a critical nature, e. g. foodstuffs, appropriate safety precautions should be taken by the plant manufacturer or user.

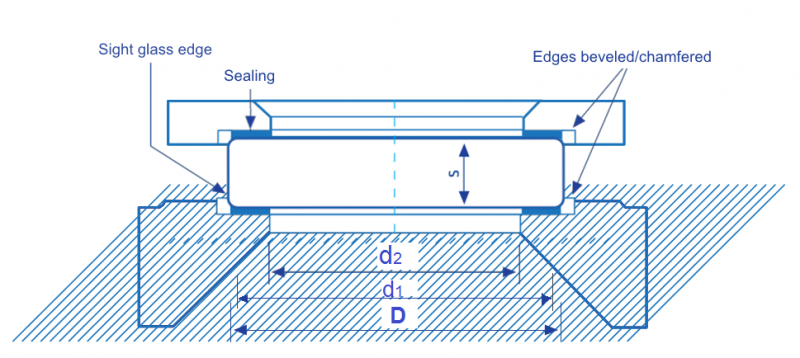

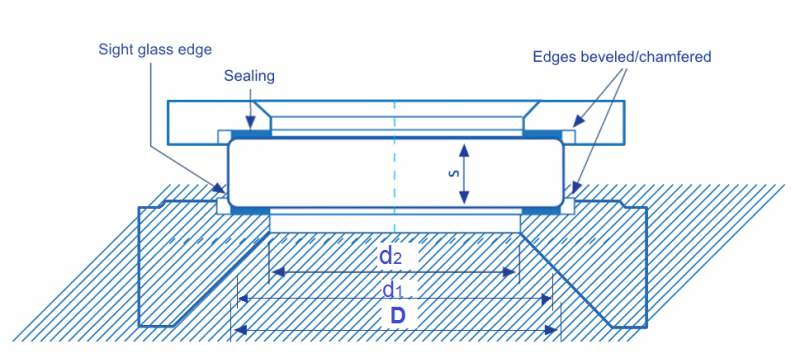

Dimensions

The method of sizing:

| Diameter D [mm] |

Width s [mm] |

Pressure [bar] |

Notes |

|---|---|---|---|

| 24 | 10 | 150 | disc special size |

| 30 | 12 | 150 | disc special size |

| 15 | 200 | disc special size | |

| 31,6 | 12,75 | 150 | disc special size |

| Aluminosilicate | |||

| 33 | 14 | 150 | disc special size |

| 33,12 | 15,95 | Aluminosilicate | |

| 34 | 17 | 200 | disc special size |

| Aluminosilicate | |||

| 35 | 7 | 25 | disc special size |

| 40 | 10 | 40 | disc special size |

| 12 | 50 | disc special size | |

| 44 | 10 | 40 | disc special size |

| 12 | 50 | disc special size | |

| 45 | 10 | 40 | acc. DIN 7080 |

| 12 | 50 | acc. DIN 7080 | |

| 50 | 10 | 25 | acc. DIN 7080 |

| 12 | 40 | acc. DIN 7080 | |

| 55 | 6,5 | 6 | disc special size |

| 10 | 25 | disc special size | |

| 60 | 10 | 16 | acc. DIN 7080 |

| 12 | 25 | acc. DIN 7080 | |

| 15 | 40 | acc. DIN 7080 | |

| 20 | 95 | disc special size | |

| 63 | 8 | 8 | disc special size |

| 10 | 16 | acc. DIN 7080 | |

| 12 | 25 | acc. DIN 7080 | |

| 15 | 40 | acc. DIN 7080 | |

| 65 | 10 | 12 | disc special size |

| 15 | 40 | disc special size | |

| 70 | 12 | 16 | disc special size |

| 15 | 25 | disc special size | |

| 75 | 12 | 16 | disc special size |

| 80 | 10 | 10 | disc special size |

| 12 | 16 | acc. DIN 7080 | |

| 15 | 25 | acc. DIN 7080 | |

| 20 | 40 | acc. DIN 7080 | |

| 86 | 12 | 10 | disc special size |

| 90 | 10 | 8 | disc special size |

| 92 | 10 | 8 | disc special size |

| 94 | 12 | 10 | disc special size |

| 95 | 10 | 6 | disc special size |

| 15 | 16 | disc special size | |

| 100 | 10 | 7 | disc special size |

| 12 | 10 | disc special size | |

| 15 | 16 | acc. DIN 7080 | |

| 20 | 25 | acc. DIN 7080 | |

| 25 | 40 | acc. DIN 7080 | |

| 105 | 15 | 16 | disc special size |

| 110 | 12,5 | 10 | disc special size |

| 20 | 25 | disc special size | |

| 113 | 15 | 10 | disc special size |

| 115 | 15 | 10 | disc special size |

| 120 | 10 | 4 | disc special size |

| 15 | 10 | disc special size | |

| 18 | 16 | disc special size | |

| 125 | 15 | 10 | acc. DIN 7080 |

| 20 | 16 | acc. DIN 7080 | |

| 25 | 25 | acc. DIN 7080 | |

| 30 | 40 | disc special size | |

| 130 | 15 | 10 | disc special size |

| 135 | 15 | 8 | disc special size |

| 25 | 25 | acc. DIN 7080 | |

| 140 | 15 | 8 | disc special size |

| 150 | 10 | 2 | disc special size |

| 15 | 8 | disc special size | |

| 20 | 10 | acc. DIN 7080 | |

| 25 | 16 | acc. DIN 7080 | |

| 30 | 25 | acc. DIN 7080 | |

| 160 | 20 | 12 | disc special size |

| 170 | 15 | 5 | disc special size |

| 20 | 10 | disc special size | |

| 175 | 20 | 10 | acc. DIN 7080 |

| 25 | 16 | acc. DIN 7080 | |

| 30 | 25 | acc. DIN 7080 | |

| 200 | 20 | 8 | acc. DIN 7080 |

| 25 | 10 | acc. DIN 7080 | |

| 30 | 16 | acc. DIN 7080 | |

| 210 | 25 | 10 | disc special size |

| 250 | 20 | 4 | disc special size |

| 25 | 8 | acc. DIN 7080 | |

| 30 | 10 | acc. DIN 7080 | |

| 265 | 30 | 8 | acc. DIN 7080 |

Note: if in the column Notes otherwise stated, borosilicate glass "extra hard" is used

Round sight glasses are delivered separately or in a set with gaskets and mica shield.

If you can not find the size - please contact us.

Tolerances

| Diameter (d1): d1 ≤ 125 mm 125 mm < d1 ≤ 200 mm d1 > 200 mm |

± 0,5 mm ± 0,8 mm ± 1,0 mm |

Thicknes (s): |

|

|

|

Flatness (e): |

|

Parallelity (p): |

|

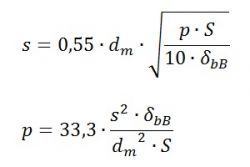

Calculation of the glass thickness

s - theoretical minimum glass thicknes [mm]

s - theoretical minimum glass thicknes [mm]

dm => (d1+d2)/2 => average sealing diameter [mm]

d1 - glass and sealing outside diameter [mm]

d2 - sealing inside diameter [mm]

p - permisible presure [bar]

δbB - min. value of surface comressive stress [N/mm2]

S - safety factor